In the fast-paced world of modern manufacturing, accuracy, speed, and flexibility are essential. Businesses across industries are constantly looking for ways to optimize production, reduce costs, and maintain consistent quality. Among the advanced fabrication technologies available today, laser cutting services have emerged as one of the most reliable and effective solutions for meeting these demands.

From intricate designs to large-scale industrial applications, these services play a critical role in shaping metals, plastics, and other materials with unmatched precision. This article explores how companies and industries benefit from laser cutting, highlighting the versatility, advantages, and opportunities provided by this advanced technology.

Understanding Laser Cutting Services

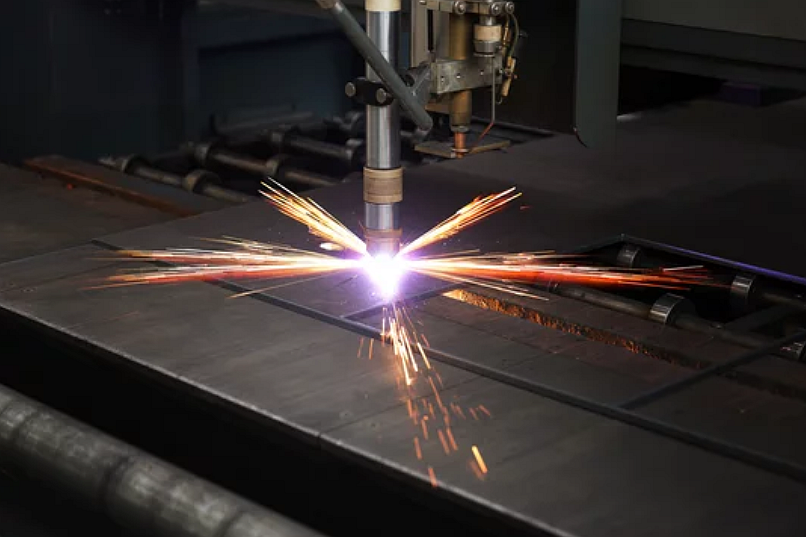

Laser cutting services use concentrated beams of light to cut, engrave, or mark a variety of materials. Unlike traditional cutting methods, the process does not rely on physical contact, which significantly reduces wear and tear on tools and ensures a clean, precise cut every time.

This technology is widely used in industries such as automotive, aerospace, electronics, medical devices, and consumer products. Whether it’s mass production or specialized one-off designs, the ability to achieve fine details and complex geometries makes laser cutting a preferred choice for businesses seeking both efficiency and innovation.

Why Laser Cutting Services Are Essential for Modern Manufacturing

1. Superior Accuracy

One of the biggest advantages of laser cutting services is their incredible accuracy. Computer-controlled systems guide the laser with microscopic precision, making it possible to cut even the most complex patterns flawlessly.

2. High Speed and Efficiency

In industries where time equals money, laser cutting excels. Compared to manual methods, the speed of the process is significantly higher, which boosts productivity and shortens turnaround times.

3. Versatility in Applications

Laser cutting is not limited to metals. With custom laser cutting services, manufacturers can work with wood, acrylic, plastic, and composites. This adaptability makes it useful for both industrial applications and creative projects like signage, decorative panels, and prototypes.

Exploring Different Types of Laser Cutting Solutions

Manufacturers and designers often seek the right partner to provide tailored laser cutting solutions for their needs. Here are some of the common categories:

-

Industrial Fabrication – For heavy-duty cutting of stainless steel, carbon steel, and aluminum used in machinery, automotive, and aerospace parts.

-

Decorative Applications – Intricate patterns for architectural projects, interior design, and branding elements.

-

Prototyping and Small Batch Production – Quick turnaround and precision make it ideal for testing and refining product designs.

-

Medical Devices and Electronics – Where precision and clean finishes are absolutely essential.

By choosing experienced laser cutting experts, companies ensure that every project meets high-quality standards, regardless of its complexity or material type.

The Role of Online Laser Cutting Services

In today’s digital-first world, convenience is as important as quality. Online laser cutting services allow businesses to upload their designs, select materials, and receive instant quotes without leaving their office. This streamlined approach saves valuable time, reduces communication errors, and accelerates production.

For startups, small businesses, and even large enterprises, online platforms make it easier to scale projects quickly while still ensuring reliable accuracy. The rise of these digital solutions reflects how the manufacturing industry is adapting to modern demands for speed and accessibility.

Benefits of Working with Laser Cutting Experts

When businesses invest in laser cutting services, they aren’t just paying for technology—they’re also relying on the skill and experience of professionals. Partnering with true laser cutting experts provides several advantages:

-

Optimized Design Consultation – Skilled technicians can recommend adjustments to ensure cost-effective cutting without compromising quality.

-

Material Selection Guidance – Professionals help in choosing the right material for durability, appearance, and performance.

-

Quality Assurance – Every project is checked for consistency, ensuring cuts are smooth, edges are clean, and dimensions are accurate.

This combination of technology and expertise delivers results that generic or inexperienced providers simply cannot match.

Custom Laser Cutting Services: Tailored to Every Project

Not every project can be handled with a one-size-fits-all approach. That’s where custom laser cutting services come into play. These specialized solutions allow businesses to create unique designs, branded components, and personalized products with complete flexibility.

For example:

-

Architectural firms can design complex metal facades.

-

Retail businesses can create unique signage.

-

Industrial companies can order highly specific parts for equipment.

Custom services ensure that each requirement—no matter how unique—is addressed with precision and care.

Key Industries Benefiting from Laser Cutting Services

Automotive and Aerospace

From engine components to lightweight aluminum parts, laser cutting services provide the precision required in industries where safety and performance are critical.

Electronics

The ability to cut micro-level patterns makes this technology ideal for circuit boards and delicate electronic housings.

Healthcare

Surgical tools and medical devices require extremely clean, accurate cuts that only laser technology can consistently provide.

Construction and Architecture

Decorative panels, signage, and structural elements benefit from the flexibility of laser cutting solutions.

How Laser Cutting Solutions Improve Business Efficiency

Investing in laser cutting services not only enhances quality but also drives business efficiency. With faster turnaround, lower material waste, and higher repeatability, companies can save both time and money. Additionally, the precision ensures fewer errors, reducing the need for costly rework.

When combined with online laser cutting services, the entire process—from design to delivery—becomes more streamlined, supporting businesses in staying competitive in demanding markets.

Choosing the Right Partner for Laser Cutting Services

When selecting a provider, businesses should prioritize:

-

Experience and Reputation – Proven track records ensure consistent quality.

-

Technology and Equipment – Modern, well-maintained machines deliver the best results.

-

Customer Support – Clear communication and responsive service are essential for project success.

-

Flexibility – Providers offering both standard and custom laser cutting services can handle a broader range of needs.

The Future of Laser Cutting Services

As manufacturing continues to evolve, laser cutting services will play an even more prominent role. With automation, AI integration, and smart manufacturing, future solutions will become faster, more precise, and more cost-efficient.

From complex industrial applications to creative custom projects, this technology will remain at the heart of innovation. Businesses that embrace these solutions now will position themselves for long-term success in a highly competitive marketplace.

Conclusion

Laser cutting services represent the perfect balance of precision, speed, and flexibility. They provide businesses with the tools to innovate, reduce waste, and deliver exceptional products across industries. Whether through custom laser cutting services, convenient online laser cutting services, or the guidance of laser cutting experts, companies can achieve greater efficiency and higher-quality results.

As industries demand smarter and faster solutions, laser technology will continue to stand out as an indispensable part of modern manufacturing.